Products

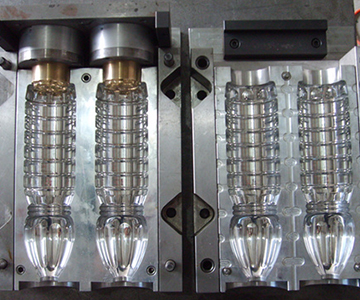

Blow Mould

Blow molding ( BrE moulding ) is a manufacturing technique by way of which hole plastic components are shaped. In popular, there are 3 fundamental types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding procedure begins with melting down the plastic and forming it right into a parison or within the case of injection and injection stretch blow moulding (ISB) a preform. The parison is a tube-like piece of plastic with a hole in a single stop via which compressed air can pass.

The Blow Moulding Process

The blow moulding procedure, in comparison with injection moulding, is a low strain process with typical blow air pressures around 25 to a hundred and fifty psi. There are several extraordinary kinds of blow moulding. an outline of each procedure is outlined under:

Injection Blow Moulding

Injection blow moulding is used inside the manufacturing of huge portions of hole plastic gadgets. The technique starts offevolved with the injection moulding of a polymer onto a middle pin that's then circled to a blow moulding station to be inflated and cooled. usually used to make small clinical and single serving bottles, injection blow moulding is the least-used of all blow moulding procedures.

Extrusion Blow Moulding

Extrusion blow moulding may be used to procedure many extraordinary polymers which include polyethylene, polyvinyl chloride, polypropylene and greater. The manner starts offevolved with the traditional downward extrusion of a tube. while the tube reaches the favored period the mildew is closed catching and protecting the neck quit open and pinching the bottom quit closed. Then a blow-pin is inserted into the neck quit of the new tube to shape the threaded opening and inflate the tube within the mildew hollow space. whilst the mildew is absolutely cooled it's miles opened to eject the bottle and the excess plastic is trimmed from the neck and backside regions.

Stretch Blow Moulding

the primary programs of stretch blow moulding consists of jars, bottles, and similar containers as it produces objects of amazing visual and dimensional exceptional as compared to extrusion blow moulding. The manner first calls for the plastic to be injection moulded into a 'preform' with the completed necks (threads) of the bottles on one end.